Air Diffusers

Air Diffusers for Water Treatment: Enhancing Oxygen Transfer and Efficiency

In wastewater treatment, air diffusers are essential components for aeration systems. They disperse air into water, enabling the oxygenation required for biological treatment processes. Among various diffuser types, fine bubble and coarse bubble diffusers play different roles, depending on the treatment goals and wastewater characteristics.

This article explores the role of air diffusers in water treatment, compares membrane materials like EPDM and Silicone Rubber, and presents key specifications to help engineers and operators make informed choices. It’s especially useful for anyone involved in air diffusion systems in wastewater treatment plants (WWTPs).

What Are Air Diffusers?

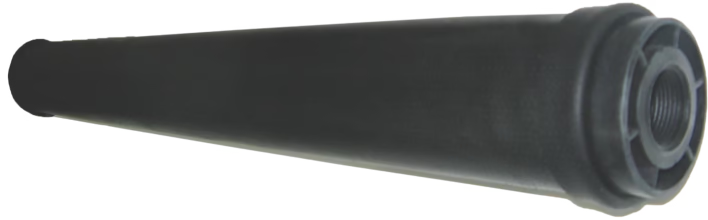

Air diffusers are devices that introduce air into wastewater through pores in a membrane, forming either fine or coarse bubbles. The air diffusion process enables oxygen transfer, measured as SOTE (Standard Oxygen Transfer Efficiency), which is critical for aerobic biological processes. Higher SOTE translates to more efficient treatment and lower energy consumption.

Fine Bubble vs Coarse Bubble Diffusers

Fine bubble diffusers create small bubbles (1–3 mm), offering high SOTE and longer retention time in the tank. They are ideal for activated sludge, MBR, and SBR systems.

Coarse bubble diffusers produce larger bubbles (4–10 mm), which rise faster. They offer better mixing but lower oxygen transfer efficiency. These are useful in equalization tanks, aerobic digesters, and high-solids environments.

While coarse bubbles are suitable for mixing-heavy applications, fine bubbles are the preferred choice for oxygen-intensive biological treatment.

Applications of Air Diffusion in Water Treatment

Municipal wastewater treatment

Industrial effluent treatment

Sludge stabilization

Aquaculture and fish farming

Effluent equalization tanks

Fine Bubble Diffuser Specifications (EPDM Membrane)

Below is a table detailing common models with EPDM membranes, which are widely used for general-purpose wastewater aeration:

| Parameter | Model 1 (63×610 mm) | Model 2 (63×1000 mm) |

|---|---|---|

| Diameter | 63 mm | 63 mm |

| Length | 610 mm | 1000 mm |

| Membrane | EPDM | EPDM |

| Support Pipe | PVC | PVC |

| End Clamps | SS-304 | SS-304 |

| Air Flow | 1–5 m³/h | 2–10 m³/h |

| End Connection | 3/4″ BSP | 3/4″ BSP |

These diffusers are highly compatible with conventional treatment systems and offer good chemical resistance and mechanical strength.

Fine Bubble Diffuser Specifications (Silicone Membrane)

For environments with oily or high-fouling wastewater, Silicone Rubber membranes are a better choice due to their superior flexibility and fouling resistance.

| Parameter | Model 1 (63×610 mm) | Model 2 (63×1000 mm) |

|---|---|---|

| Diameter | 63 mm | 63 mm |

| Length | 610 mm | 1000 mm |

| Membrane | Silicone Rubber | Silicone Rubber |

| Support Pipe | PVC | PVC |

| End Clamps | SS-304 | SS-304 |

| Air Flow | 1–5 m³/h | 2–10 m³/h |

| End Connection | 3/4″ BSP | 3/4″ BSP |

Silicone membranes maintain consistent bubble performance over long durations and are ideal for continuous operation systems or industrial effluents with high grease content.

Comparing EPDM and Silicone Rubber Membranes

| Feature | EPDM Membrane | Silicone Rubber Membrane |

|---|---|---|

| Chemical Resistance | High (general use) | Excellent (especially in oily environments) |

| Flexibility | Moderate | High |

| Anti-fouling Property | Moderate | Excellent |

| Cost | More economical | Slightly more expensive |

| Application Suitability | Municipal and industrial | Industrial, food, or grease-heavy effluents |

Both materials are excellent in terms of air diffusion efficiency, but choosing the right one depends on your specific wastewater characteristics and maintenance preferences.

Why Fine Bubble Diffusers Matter

1. Higher Oxygen Transfer Efficiency (SOTE)

Fine bubbles provide a larger surface area, resulting in higher SOTE and better oxygen transfer rates.

2. Energy Savings

With greater oxygenation per cubic meter of air, these systems require less blower power, reducing operational costs.

3. Improved Mixing and Process Control

Although not as vigorous as coarse bubble diffusers, fine bubble systems still provide enough mixing to prevent sludge settlement and promote uniform biological activity.

4. Scalability and Customization

You can scale your aeration system easily by adding more diffusers, whether for new tanks or process upgrades.

Choosing the Right Diffuser

When choosing between fine bubble and coarse bubble diffusers, consider:

Oxygen demand

Wastewater type (greasy, chemical, high-solids)

Tank depth and volume

Energy costs

Maintenance capabilities

For most biological treatment applications, fine bubble diffusers with either EPDM or Silicone Rubber membranes are optimal due to their balance of cost, performance, and lifespan.

Installation and Maintenance Best Practices

Use 3/4″ BSP end connections for leak-free installations.

Maintain recommended air flow (e.g., 1–5 m³/h or 2–10 m³/h depending on diffuser size).

Inspect membranes periodically for fouling or clogging.

Use SS-304 clamps to ensure long-term corrosion resistance.

Clean or replace membranes based on operating conditions and load levels.

Conclusion

Air diffusers for water treatment are vital components in any wastewater treatment setup. With proper selection and maintenance, they can deliver high oxygen transfer efficiency (SOTE) while reducing energy usage and improving treatment outcomes. Whether you choose EPDM for general use or Silicone Rubber for industrial challenges, both materials offer reliable performance when paired with fine bubble air diffusion systems.

Additionally, for tanks requiring intense mixing or handling of high-solids sludge, coarse bubble diffusers remain a valuable option. The key is aligning your diffuser type, material, and sizing with the specific treatment goals and water quality.

For engineers, operators, and plant designers looking to enhance system efficiency, selecting the right air diffuser is a foundational decision that affects long-term performance, cost, and compliance.

Tags:

Air diffusers for water treatment, Air diffusion, Fine bubble diffusers, Coarse bubble diffusers, EPDM membrane, Silicone rubber membrane, Wastewater aeration, Oxygen transfer, SOTE, Wastewater treatment plant, Biological treatment, Aeration system design, Energy-efficient aeration