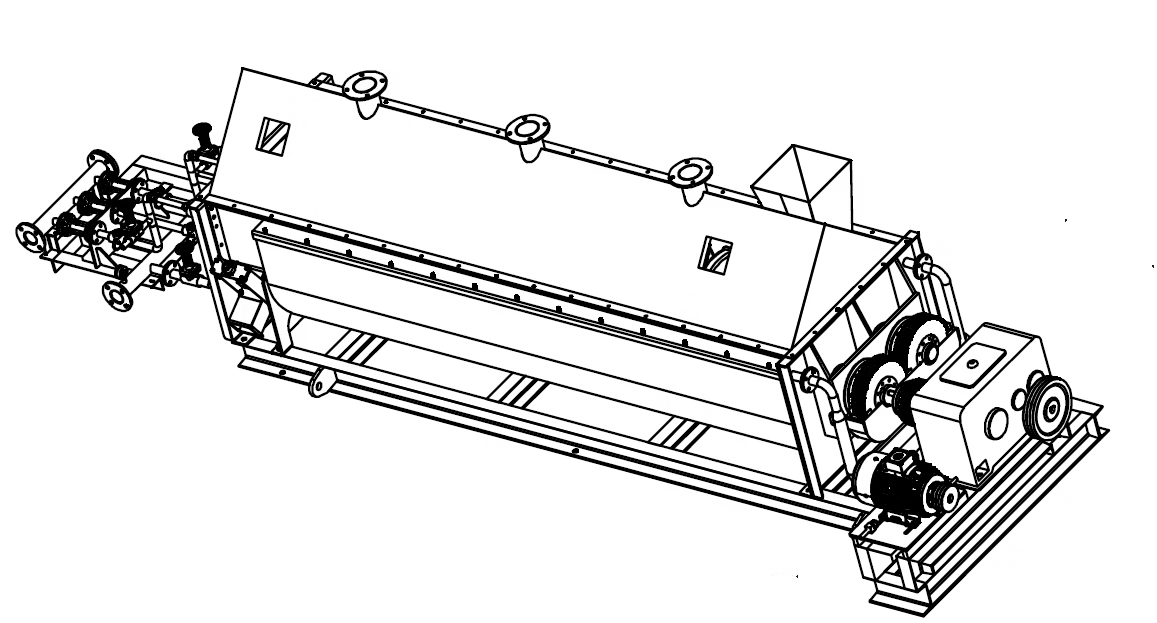

Sludge Paddle Dryer

Sludge Paddle Dryer – Efficient and Sustainable Sludge Drying Solution

The Sludge Paddle Dryer is a high-performance, energy-efficient, and reliable drying system designed for industrial and municipal sludge dewatering and drying applications. Engineered to handle a wide variety of sludges and semi-solid waste, this machine offers a low-temperature, indirect heat transfer process that ensures consistent drying performance, reduced operating costs, and minimal environmental impact.

Ideal for Effluent Treatment Plants (ETP), Sewage Treatment Plants (STP), and various industrial wastewater facilities, our Sludge Paddle Dryer transforms wet sludge into a dry, manageable, and often reusable form, thereby turning a costly waste stream into a potential resource.

What is a Sludge Paddle Dryer?

What is a Sludge Paddle Dryer?

A Sludge Paddle Dryer is an indirect-contact thermal drying device that uses hollow paddles mounted on a rotating shaft. The paddles are heated internally using steam, thermal oil, or hot water. As the sludge comes into contact with the heated surfaces, moisture evaporates, and the dried material is conveyed gradually toward the discharge outlet. Unlike direct dryers, where hot air is blown directly through the sludge, the paddle dryer provides controlled, uniform heating with virtually no dust or odor emissions.

Key Features

✅ Indirect Heating for Clean Operation

The heat is transferred through the metal walls of the paddles and trough. There’s no direct contact between the heating medium and the sludge, which means there’s no risk of combustion, contamination, or toxic emissions. This makes the paddle dryer a safe and environmentally friendly solution.

✅ Low Energy Consumption

The system operates at relatively low temperatures (typically between 100–250°C depending on the medium), and since it uses conduction rather than convection, energy losses are minimal. The high thermal efficiency results in lower operating costs and a faster return on investment.

✅ Self-Cleaning Design

The intermeshing paddles are designed not only to agitate the sludge and increase the surface area for drying but also to scrape off dried material from the heated surfaces continuously. This ensures optimal heat transfer, reduces fouling, and lowers maintenance needs.

✅ Compact Footprint

The Sludge Paddle Dryer is a compact system that requires minimal floor space. It is ideal for retrofit installations in existing ETP/STP facilities and can be integrated seamlessly with upstream and downstream processes like sludge dewatering, conveyors, and bagging units.

✅ Customizable Designs

Available in both single-shaft and twin-shaft configurations, the paddle dryer can be tailored to match specific sludge characteristics, volume capacities, and drying requirements. Materials of construction can be customized based on the corrosiveness and abrasiveness of the feedstock—ranging from stainless steel to special alloy coatings.

Working Principle

Feeding: Dewatered sludge (typically 20–30% solids) from filter presses or screw presses is fed into the dryer through a controlled inlet system.

Drying: The rotating paddles—heated via internal channels—indirectly transfer heat to the sludge. Simultaneously, the paddles agitate and mix the sludge, promoting uniform drying.

Evaporation: As the water in the sludge evaporates, the vapor is collected via a vapor dome and sent to a condenser or scrubber.

Discharge: The dried sludge, now in a powdery or granular form (typically 80–90% solids), is discharged through a screw conveyor or rotary valve for storage, incineration, or reuse.

Technical Specifications (Typical Range)

| Parameter | Value |

|---|---|

| Capacity | 100 – 5000 kg/hr |

| Moisture Reduction | From ~80% to below 10% |

| Heating Medium | Steam / Thermal Oil / Hot Water |

| Heating Surface Temp | 100–250°C |

| Power Consumption | 5–40 kW (depending on model) |

| Construction | SS304 / SS316 / Carbon Steel with Coating |

| Shaft Type | Single or Twin Shaft |

| Control System | PLC-based automation (optional) |

Advantages of the Sludge Paddle Dryer

🔹 Energy-Efficient Drying

Compared to belt dryers or fluidized bed dryers, paddle dryers consume 30–40% less energy, thanks to the indirect conduction-based design.

🔹 Minimal Emissions

With no hot air required, there’s no need for extensive exhaust gas treatment systems, and odor emissions are significantly reduced.

🔹 Safe Operation

The low operating temperatures and lack of airborne dust reduce explosion risk, making it compliant with ATEX and OSHA safety norms in hazardous environments.

🔹 Robust and Durable

Heavy-duty paddles and thick-walled troughs ensure the dryer can withstand abrasive sludge, thermal stresses, and high usage without significant wear and tear.

🔹 Low Maintenance

Few moving parts, along with a self-cleaning mechanism, result in low maintenance downtime and high operational reliability.

🔹 Automation Ready

With optional PLC-based control systems, the dryer can be fully automated for continuous operation, remote monitoring, and real-time process feedback.

Applications Across Industries

The Sludge Paddle Dryer is widely applicable in:

Municipal STPs and ETPs – for drying sewage and effluent sludge.

Chemical Industries – to treat process sludge, brine waste, and gypsum.

Food & Beverage – for drying organic waste and byproducts.

Pharmaceuticals – for handling bio-waste and active residue sludge.

Textile & Dyeing Plants – for drying color-laden, fibrous sludge.

Tanneries and Leather Processing – for chrome-containing sludge.

Paper and Pulp – for treating fiber-rich wastewater sludge.

Power Plants – for drying bottom ash, fly ash, or FGD sludge.

Environmental Impact and Sustainability

By reducing the volume and weight of sludge, the paddle dryer directly helps in cutting transportation and disposal costs. Dried sludge can be:

Used as fuel (calorific value up to 3500–4500 kcal/kg)

Applied in agriculture (after stabilization and compliance testing)

Safely landfilled at a lower cost

Co-processed in cement kilns or waste-to-energy plants

This supports circular economy models by promoting reuse and energy recovery.

Why Choose Our Paddle Dryer?

At [Your Company Name], we combine advanced engineering with 30+ years of sludge management experience. Our Paddle Dryer units are indigenously manufactured, backed by a strong service network, and designed to meet the unique needs of Indian industries. From concept to commissioning, we provide:

Customized design and capacity scaling

Full system integration (including feeding, drying, vapour condensation, and discharge)

Installation, commissioning, and training

On-site and remote after-sales support

Conclusion

The Sludge Paddle Dryer is a robust, scalable, and sustainable drying solution that helps industries and municipalities reduce waste volumes, save on disposal costs, and move toward zero-waste goals. Whether you are upgrading an existing sludge treatment system or setting up a new facility, our dryer offers unmatched efficiency, safety, and ROI.

Let us help you transform sludge from a liability to an asset—efficiently, sustainably, and profitably

What is a Sludge Paddle Dryer?

What is a Sludge Paddle Dryer?