Blog Posts

Commercial RO System: Essential Guide Understanding the Process A commercial Reverse Osmosis (RO)...

Understanding Sequencing Batch Reactors (SBR) and Their Importance in Municipal Sewage Treatment...

Agitated Thin Film Dryer in Zero Liquid Discharge (ZLD) Systems Zero Liquid Discharge (ZLD) systems...

Mechanical Vapor Recompression (MVR) for Wastewater Treatment Mechanical vapor recompression (MVR)...

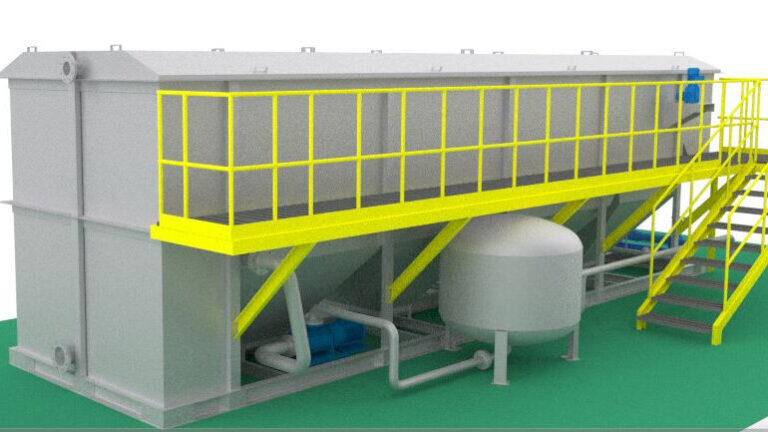

Enhancing Water Treatment Efficiency with Dissolved Air Flotation Introduction: In the realm of...

Processes and Components in Water Filtration Plants Water is the elixir of life, essential for...

Understanding Water Desalination Water scarcity is an increasingly pressing issue around the globe...

Processes and Components in Water Filtration Plants Water is the elixir of life, essential for...

Advancements in Mining Wastewater Treatment: Pioneering Technological Innovations Introduction:In...